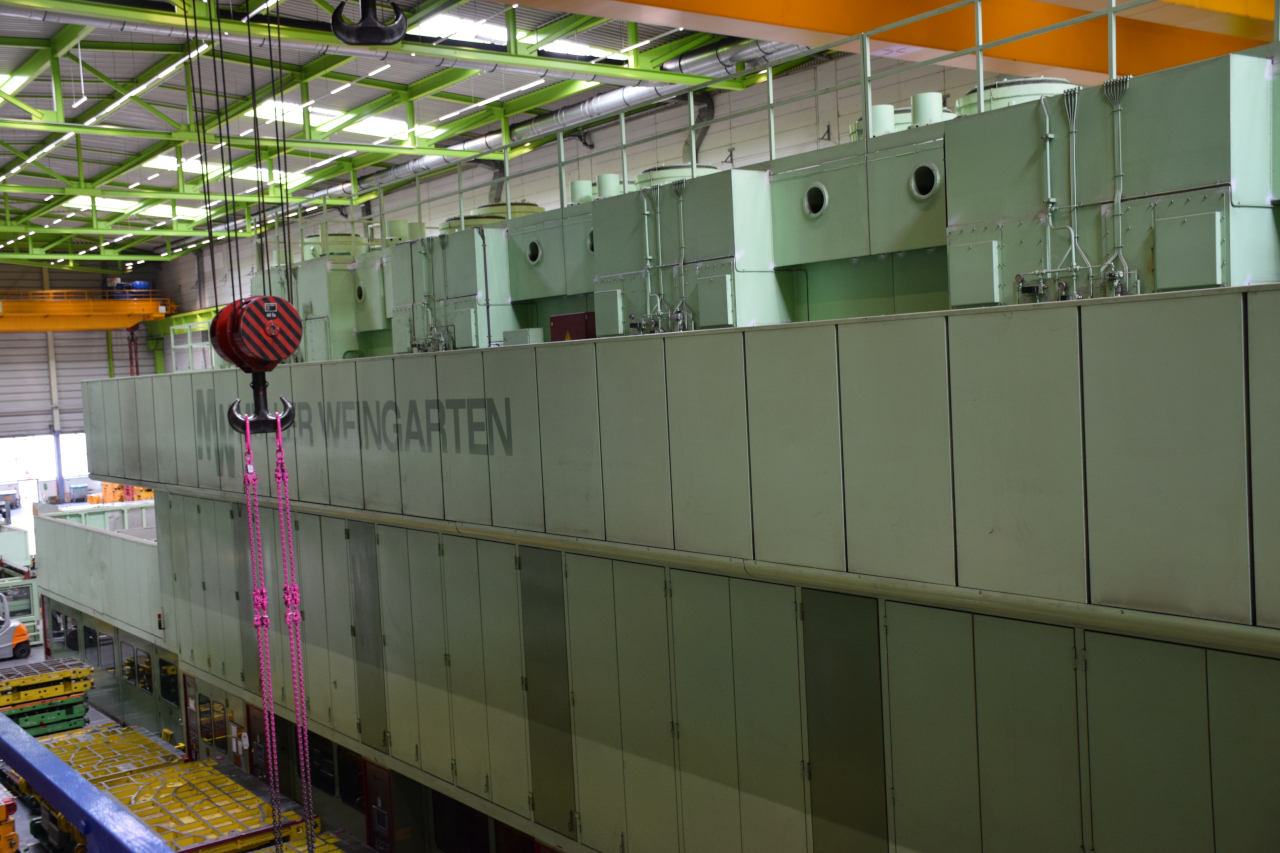

Dismantling and Transport of Müller-Weingarten S 7300.06.260 press line at Press Shop

We successfully completed the dismantling and loading of the Müller-Weingarten S 7300.06.260 Press Line at a press shop, a complex operation that involved meticulous planning and coordination. This press line, with a maximum weight of 250 tons for the press head, required specialized equipment and expert handling throughout the entire process.

Key Operations:

Dismantling Process: The entire dismantling took a total of 6 months, involving a highly skilled team of supervisor, electrical engineers, mechanics, and packers. The team carefully disassembled each component of the press line to ensure its safe removal and transport. This required precise coordination between different experts to manage the electrical, mechanical, and packaging aspects of the dismantling.

Lifting of Large Components: The heavier parts, including the press head, were lifted using a special traverse lifting system. This system was essential for safely handling the oversized and heavy components, ensuring there was no risk of damage during the process.

Transportation: Once the dismantling was completed, the press line was transported in stages. The largest parts, including the press head, were moved using heavy trucks to the Neckar area. From there, the machinery was transported by ship to its final destination. The transport logistics were carefully planned to ensure the safe and timely arrival of the equipment.

This dismantling and transport project required the expertise of a dedicated team working together to meet deadlines, ensure safety standards, and preserve the integrity of the equipment. The success of this operation was a testament to the precision, expertise, and teamwork involved.

If you’re looking for reliable dismantling and transport services for heavy machinery, our experienced team is equipped to handle even the most complex operations with care and efficiency.