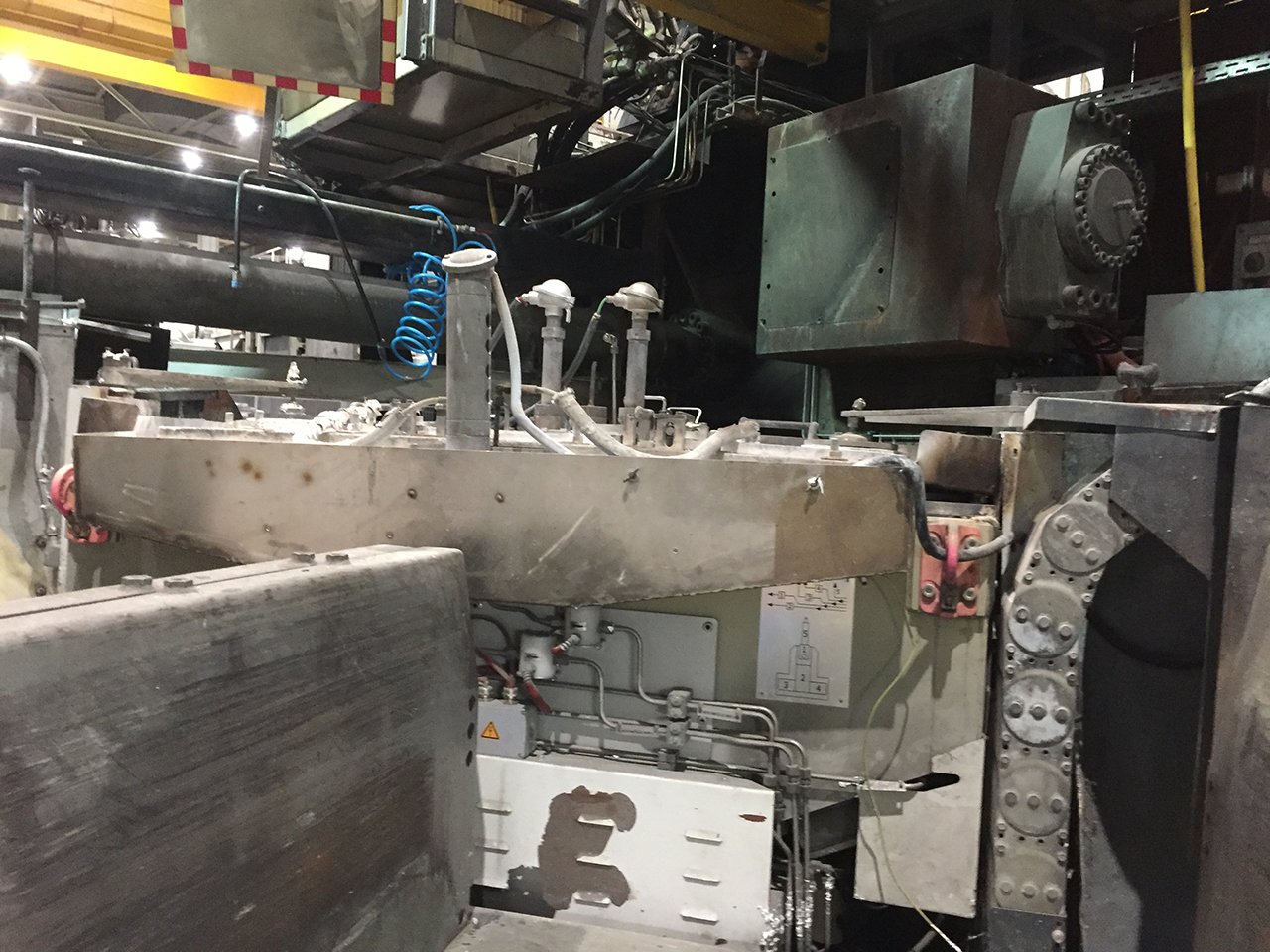

Used Rauch Melting and Holding Furnaces for Magnesium and Zinc Die Casting

We offer used Rauch melting and holding furnaces, designed specifically for the demanding needs of magnesium and zinc die casting operations. Rauch furnaces are known for their durability, precision, and efficient performance, providing optimal temperature control to ensure high-quality metal processing. These furnaces are ideal for melting and holding non-ferrous metals like magnesium and zinc, which require careful temperature regulation due to their unique properties.

Used Rauch Melting Furnaces

Rauch melting furnaces are engineered to efficiently melt magnesium, zinc, and other non-ferrous metals while maintaining precise control over temperature and energy consumption. These furnaces are built to handle the high temperatures required for melting these metals, ensuring consistent and uniform metal quality for die casting processes.

- Key Features:

- High-Efficiency Heating: Advanced heating systems for fast and energy-efficient melting, reducing fuel consumption and increasing throughput.

- Precise Temperature Control: Ensures accurate temperature management for magnesium and zinc, which are sensitive to temperature fluctuations during melting.

- Safety Features: Designed with safety in mind for melting reactive metals like magnesium, reducing the risk of fire or explosion in the casting environment.

- Robust Construction: Built to withstand high temperatures and demanding operations, providing long-lasting performance in foundries.

Used Rauch Holding Furnaces

Rauch holding furnaces are designed to maintain molten magnesium and zinc at a stable, optimal temperature for extended periods, ensuring the metal remains in a liquid state without solidifying before it is needed for casting. These furnaces are essential for ensuring a continuous supply of molten metal for die casting operations, helping to maintain production efficiency.

- Key Features:

- Stable Temperature Control: Designed to hold magnesium and zinc at a constant temperature, preventing solidification and maintaining consistent metal flow during casting.

- Energy Efficient: Built to retain heat effectively, minimizing energy use and lowering operational costs.

- Durability: Made with high-quality materials that can endure continuous high-temperature operation and the specific challenges of holding reactive metals like magnesium.

- Optimized for Non-Ferrous Metals: Perfect for holding zinc, magnesium, and other non-ferrous alloys, ensuring quality metal for casting applications.

Benefits of Using Used Rauch Melting and Holding Furnaces:

- Improved Casting Quality: Maintaining precise temperature control helps prevent defects such as porosity, oxidation, and contamination in magnesium and zinc castings.

- Energy Efficiency: Rauch furnaces are designed to reduce energy consumption while maintaining optimal melting and holding temperatures, making them a cost-effective solution for your foundry.

- Increased Production Efficiency: With rapid metal melting and consistent holding, you can reduce downtime and increase throughput, ensuring continuous, efficient casting operations.

- Extended Equipment Life: The robust construction of Rauch furnaces ensures long-term operation with minimal maintenance, even under the heavy demands of magnesium and zinc casting.

- Safe Operation: Designed with safety features to prevent the risks associated with melting and holding highly reactive metals like magnesium, Rauch furnaces provide peace of mind in your production environment.

Why Choose Used Rauch Melting and Holding Furnaces?

- Proven Performance: Rauch furnaces are known for their reliability and high performance, making them a trusted choice for die casting foundries specializing in magnesium, zinc, and other non-ferrous metals.

- Cost-Effective: Used Rauch furnaces offer significant savings compared to new equipment, while still providing the durability and performance needed for high-quality die casting.

- Quick Integration: Pre-inspected and refurbished units are ready to be installed and integrated into your production line with minimal downtime.

- Comprehensive Support: We provide installation, maintenance, and operational support to ensure your used Rauch furnaces are running smoothly and efficiently.

Applications:

- Magnesium Die Casting: Perfect for melting and holding magnesium, which requires precise temperature control due to its low melting point and reactive nature.

- Zinc Die Casting: Ideal for handling zinc and its alloys in die casting operations that require stable molten metal temperatures and consistent flow.

- Non-Ferrous Metal Processing: Suitable for any die casting application involving non-ferrous metals, ensuring consistent and high-quality casting results.

If you're looking for used Rauch melting and holding furnaces for magnesium and zinc die casting, these reliable and energy-efficient systems provide excellent performance, helping you achieve consistent, high-quality castings while reducing operational costs.