Every newly produced casting has sprues, overflows and burrs. Unfortunately, even today this cannot be avoided in casting technology. That is why every casting must then be deburred in further processing. Here, unsightly burrs are removed using various methods. Deburring is relevant both technically and for occupational safety. Only by producing workpieces that are as free of burrs as possible can further mechanical processing and injury-free assembly as well as reliable fulfilment of the functions be guaranteed. Those who do not want to rely on the classic and manual fettling of castings look around for automated solutions for deburring. These are significantly more economical than old deburring solutions.

There are various specialists who offer excellent deburring presses and deburring tools with the matching automated casting handling up to complete casting cells. These can be found on die casting, gravity, tilting and low-pressure casting machines.

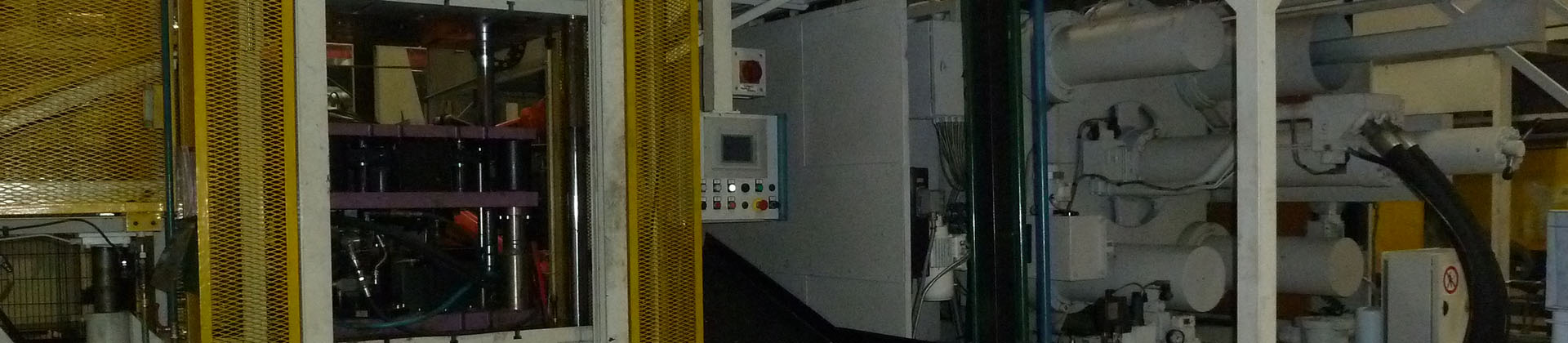

Depending on the desired application, we offer used trimming presses with C-form construction, as 3- or 4-column version and sliding/tilt table trimming presses. If we do not have the right machine in our stock, we will gladly go in search of the appropriate used machine such as deburring press, trimming press or column press for you.

Here it is always important to pay attention to a coherent overall package. Of course, technical facts such as fast cycle times, low energy consumption and intelligent control play an important role in the deburring press. But it is only really effective in combination with the right components in production.

Used trimming press: New purchase or used machine?

This question comes up again and again. With an existing machine, you know what you have. The deburring press or column press has really proven itself over the years in operation and actually delivers a good result. The purchase of a new machine would certainly bring with it up-to-date technical specifications that are appealing. But the new price of a deburring press also represents an enormous financial burden for the company.

Fiss Machines always finds the right solution for customers who are looking for an economical, energy-efficient, process- and future-proof alternative by buying a second-hand machine. It is often possible to subsequently adapt the used deburring press to the respective requirements of the customer with the appropriate accessories. In this way, the press pressure can later be freely selected by the customer according to individual requirements. The design of the tables as tilting, sliding or sliding-tilt tables is also conceivable, depending on the design. The modern controls enable convenient operation and reliable, reproducible processes. Our customers always benefit from our innovative and technically intelligent solutions for industrial used machines.

Fiss-Machines: The experts around used deburring presses

Fiss-Machines has been a popular supplier of used trimming presses for the foundry industry for 30 years. We are a sought-after partner for all topics concerning the purchase and sale of used machines for the foundry industry - for large or small companies.

From the commissioning of trimming machines or trimming presses, troubleshooting and repair on site as well as the procurement of spare parts, maintenance or transport. As far as possible, our service and support leaves no wish unfulfilled. We will be happy to advise you and take care of every detail of your order.